As the world began transitioning to relative normality in 2021, it became clear that China would not be following suit. Instead, they implemented a radical zero-Covid policy, impacting their citizens and businesses that deal with China. This article shows how western companies are coping with Chinese Covid restrictions, how they can survive and thrive in the future, and standard processes to implement sourcing and manufacturing in China.

How Western Businesses Find Manufacturing Companies In China

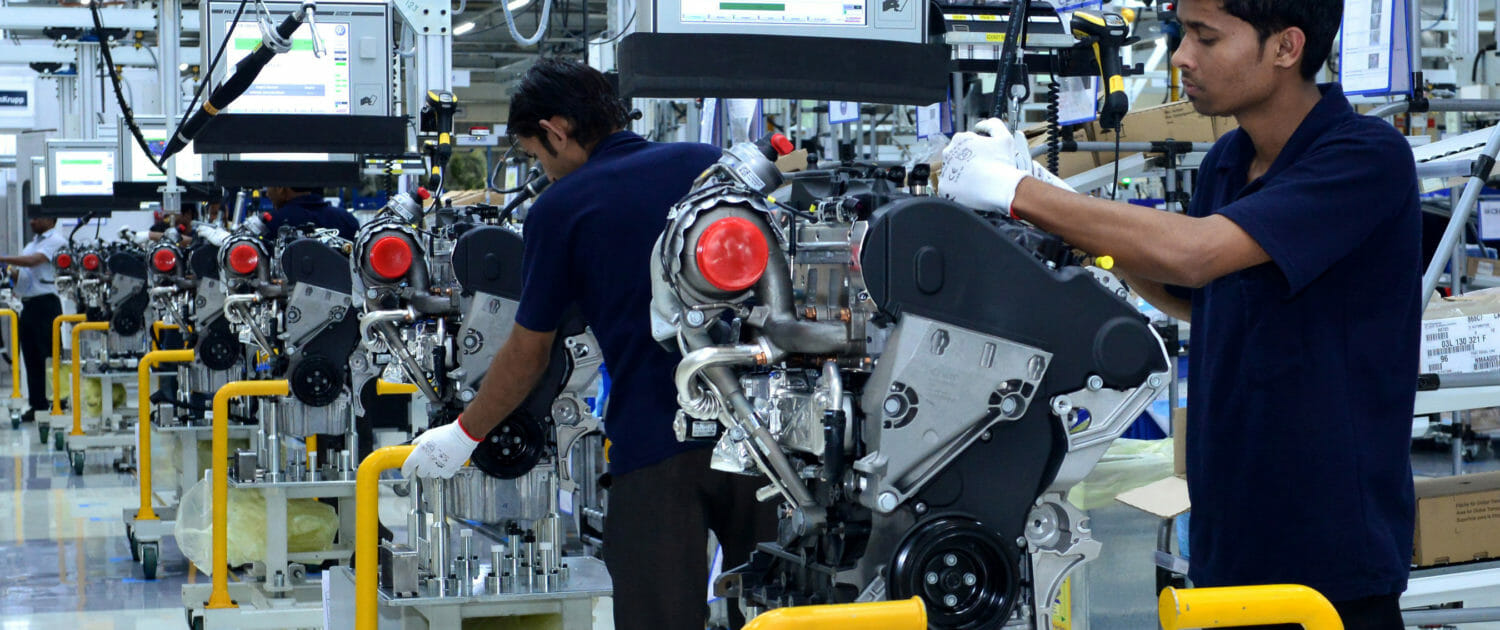

China has long been attractive to westerners because of its low manufacturing costs and the attendant opportunities for mass-market production and distribution. Chinese manufacturers allow western businesses to concentrate on research, development, and expansion. These advantages lead companies to find manufacturing companies in China, although dealing with China is very different from dealing with western businesses.

How To Find Manufacturing Companies In China

To find manufacturing companies in China, many western companies begin by researching online trading platforms such as DHGate and Alibaba. Look for reviews of companies in your industry that have dealt with suppliers of interest to you.

It’s important to differentiate between a manufacturer and a trading company since the companies often describe themselves as manufacturers when they are middlemen selling pre-existent products. If that’s so, you will make less profit. Buying from the production source means you can expect to make 5 – 20% more profit. Components for complex manufacturing are usually bought off the shelf or from other manufacturers.

Chinese trade shows are traditionally good places to find manufacturing companies in China. For 2022, webinars are a viable alternative to trade shows. Additionally, western companies are increasingly using WeChat (China’s equivalent of Facebook Messenger) and Zoom to communicate with Chinese suppliers. While these options are valuable, they can’t hope to replace in-person interaction.

Your industry trade association can also be a valuable source of information on manufacturing companies in China. Your fellow industry associates will often give you insider advice on the best suppliers to work with in China.

For more information, this article has in-depth advice on how to find a supplier.

Contract Manufacturing In China

After finding a company to manufacture goods, many companies opt for contract manufacturing in China. Traditionally, these contracts have been arranged with the manufacturer by small companies who don’t have the budget to produce goods themselves. More recently, larger companies like Apple and Hewlett Packard have outsourced their production to contract manufacturers in China. Due to the Covid crisis, Apple is outsourcing outside China for the first time.

A contract manufacturer should meet the following standards:

- Their business must be financially sound

- They should be ISO (International Organization For Standardization) certified

- They should be able to handle production efficiently

- Their factory must be clean and efficiently managed

If you wish to set up contract manufacturing in China, proceed cautiously. Ensure you know about any limits in the manufacturing process of the company under consideration. Investigate their manufacturing systems as thoroughly as possible, as manufacturing is not always as straightforward as it first appears.

China Contract Manufacturing Experts

Setting up contract manufacturing in China can be overwhelming and confusing; it’s a process with which China contract manufacturing experts can help. Sourcing companies are China contract manufacturing experts that diminish risk.

Factory Auditing

A factory audit provides a clear picture of the realities of manufacturing at a company and ensures that companies can complete products to a consistently high standard. An audit provides an in-depth analysis of production, the supply chain, research, and development, resulting in an ISO9000 factory rating.

A factory audit covers the following subjects:

- Human resources (number of workers, team structure)

- Production and trading capacity

- Equipment testing

- Company information, credit status, and legality

- Quality control (system, relevant certification, complaints procedure)

Is Their Team Bi-Lingual?

When liaising directly with a factory owner, your contact must speak good English, or misunderstandings will occur. But the Chinese company needs a bi-lingual team too. Without a bi-lingual team, problems are likely due to poor communication between your company and their team.

Ongoing Process Monitoring And Refinement

Manufacturing should be closely supervised by your company, ensuring that the production standards your company stipulate are maintained. We recommend a representative for your company or a China sourcing agent who will supervise manufacturing on your behalf.

A good sourcing agent will constantly look for ways to improve efficiency and implement revised processes to speed up production and increase profits.

Ensure that you have addressed quality control standards before production begins. Finished products should be of a consistently high standard. Quality control is often lacking in Chinese manufacturing; your manufacturer must understand that you need high-quality finished products.

The Current Outlook For Western Businesses In China

At this time, it is unquestionably difficult for westerners to implement the necessary processes to establish working relationships with Chinese companies. Established west-east partnerships are faring better.

The US Chamber of Commerce reports that only a fifth of their members say they are relocating their business due to Chinese Covid restrictions. That may change if finished goods output decreases and essential components become difficult to obtain.

At the same time, there has been a mass exodus from China; about 50% of US and China ex-pats have returned home. Most global businesses are continuing to operate in China. Some small companies don’t have the option of relocation because their businesses are in the contract manufacturing system — small companies are committed to continuing to work in China.

In what are unprecedented times, most global businesses have no long-term strategy in place. Many hope for support from their home government if supply chain relocation is necessary.

Sourcing From Vietnam

Difficulties in sourcing and rising costs in China have made trade increasingly challenging with the west. Western businesses seeking an alternative are now looking to Vietnam, which is a beneficiary of the China+1 strategy; based on minimizing geopolitical unrest and diversifying trade with other countries.

A large part of Vietnam’s economy is underdeveloped, but Vietnam benefits from being close to China. Low cost production, shipping, and labor are among the advantages that make Vietnam attractive to western companies. Western companies wishing to source from Vietnam should observe due diligence — it’s essential since Vietnam is less developed than China.

Post-Covid Business Trends In China

Some opportunities for growth in Chinese business represent positive signs for the future, not just for China but the western businesses that deal with them.

Increased digitization affects B2C companies and previously less digitized B2B markets. As a leader in digital B2C digitized transactions, this will affect China. According to mckinsey.com, China accounts for 46 percent of the global e-commerce trade. The increase in digital consultations and viewings, and 5G internet, are increasing the use of digital technology. As companies adapt to these new technologies, trading will be faster and more efficient.

Covid-19 has increased business competition; there is risk and reward. Companies ready to adapt to the trend of increased digitization stand to benefit from lean and increasingly agile supply chain technology.

China’s logistics industry already demonstrates increased effectiveness as a fundamental part of the supply chain. There is expected growth in areas like air cargo and warehouse automation.

Businesses able to adjust and keep pace with sustainability to benefit the environment and the well-being of the people will have the opportunity to thrive. These businesses should position themselves to implement the radical changes necessary to survive.

Working With A China Sourcing Agent

Initiating and maintaining business in China is complex at the best of times. These are the basic steps to begin sourcing in China. Sourcing is implemented effectively with a China sourcing agent.

Other duties of a sourcing agent include sourcing raw materials, production planning, personnel, and factory equipment.

A good sourcing agent will help you avoid the problems that plague western companies who attempt to go it alone in China. For example, quality control standards can slip without constant supervision. The sample products you receive from a company may be superior to your mass-produced order. Product processing supervision is essential.

There may be production delays due to employee absence. Machines can break down, or the manufacturing process may encounter unexpected difficulties. A reliable China sourcing agent will provide first-hand information and proactively solve problems.

Avoid unsupervised manufacturing. If a Chinese manufacturer tells you about any production problems that cause quality control standards to lapse, can you trust them? A sourcing agent will give you first-hand knowledge of any manufacturing problems.A China sourcing agent will assist you with all elements of sourcing, production, and shipping, minimizing risk and simplifying the complexities involved in partnering with a Chinese manufacturer.

Contact Us

Follow Us